ANJIE-W101

Spiral Wound Gaskets are made of a preformed thin metallic strip combined with a soft sealing composite material, wound together under pressure to energize the sealing element to act like a spring when compressed between two flange faces. The sealing element can be used stand-alone or in conjunction with inner and/or outer rings depending on the application.It is the precision-engineered solution for flanged joints, heat exchangers, boiler handholes, manholes, and other high-temperature, high-pressure applications—providing resistance to virtually every known corrosive and toxic element.

Spiral wounds are available in a full range of styles and materials and are manufactured in accordance with ASME B16.20 for use in all industry flanges, including ASME/ANSI B16.5, ASME B 16.47, Series A & B.

Specification

· Material: composite material of metal and nonmetal.

· Metal: stainless steel 201, 304, 316.

· Nonmetal: asbestos, rubber, PTFE and so on.

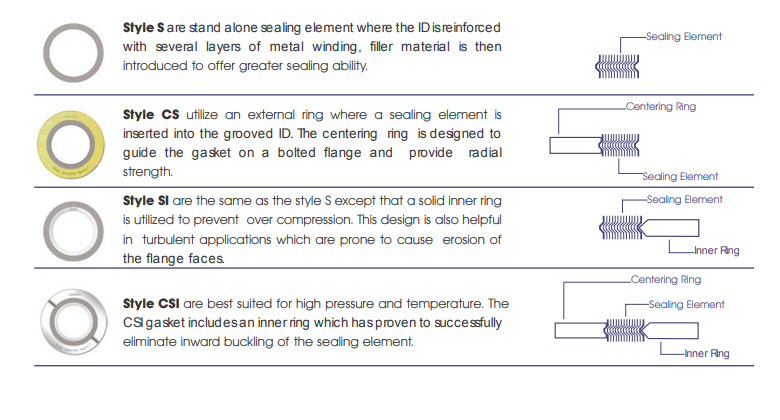

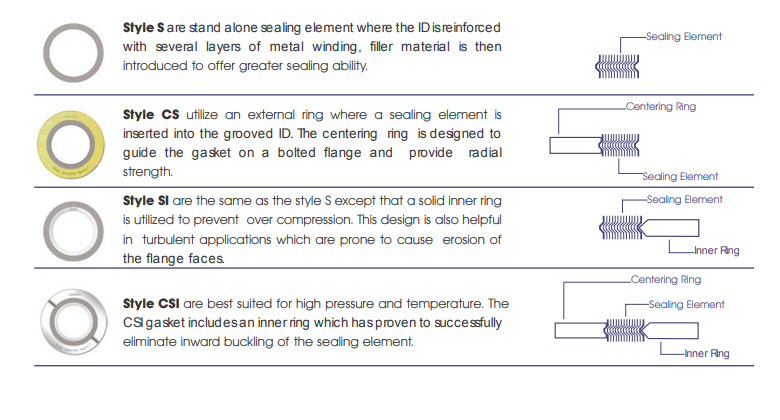

· Classification: Style S, Style CS, Style SI, Style CSI.

Spiral Wound Gaskets are made of a preformed thin metallic strip combined with a soft sealing composite material, wound together under pressure to energize the sealing element to act like a spring when compressed between two flange faces. The sealing element can be used stand-alone or in conjunction with inner and/or outer rings depending on the application.It is the precision-engineered solution for flanged joints, heat exchangers, boiler handholes, manholes, and other high-temperature, high-pressure applications—providing resistance to virtually every known corrosive and toxic element.

Spiral wounds are available in a full range of styles and materials and are manufactured in accordance with ASME B16.20 for use in all industry flanges, including ASME/ANSI B16.5, ASME B 16.47, Series A & B.

Specification

· Material: composite material of metal and nonmetal.

· Metal: stainless steel 201, 304, 316.

· Nonmetal: asbestos, rubber, PTFE and so on.

· Classification: Style S, Style CS, Style SI, Style CSI.